AFT xStream™ 2

Steam & Gas Transient Analysis Software

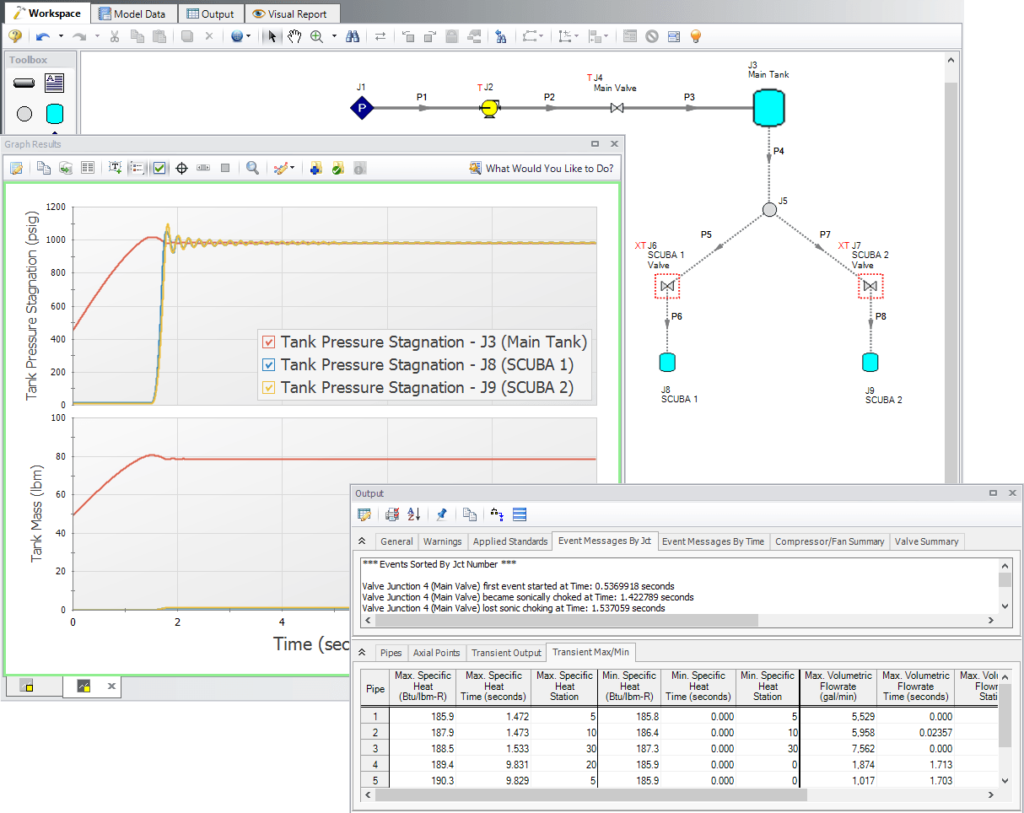

AFT xStream is a powerful fluid dynamic simulation tool for high-speed, acoustic transients that occur in steam and gas piping systems. Uncertainty in design and operations costs money and time. Now you can accurately simulate how your steam and gas systems will respond to potentially disruptive transient events.

Simulate and Solve Your Challenging Steam and Gas Transient Problems

- Accurately simulate high-speed transients in steam and gas piping systems including choked flow conditions

- Evaluate overall system response and transient pipe forces after steam and gas turbine trips

- Predict transient supply pressures, temperatures and flows to operating gas compressors and turbines when one trips offline

- Simulate tank blowdowns and charging, and how long it takes to reach desired pressures

- Predict transient pressures and flows due to heat exchanger tube ruptures

- Easily change system input data including transient valve positions, compressor operation, control set points, pressures, temperatures and more

- Initiate transients based on time or events in the system

AFT xStream is designed for fluid systems containing the below fluids and more:

Steam

Compressed Air

Process Gases

Hydrogen & Natural Gas

Typical Applications

- Ensure pressure, temperature and flow extremes are within design allowables

- Determine imbalanced pipe forces for sizing structural supports

- Troubleshoot existing systems to determine the cause of operational problems

How does it work

AFT xStream™ incorporates a highly accurate steady-state solver which provides seamless transfer of initial conditions to the transient analysis. Steady-state solutions are determined using a modified Newton-Raphson matrix iteration plus proprietary methods developed by AFT. A specialized Method of Characteristics is used to solve the transient mass, momentum and energy equations of pipe flow.

Primary Features of AFT xStream™ 2

- Built-in steady-state solver to automatically initialize system before the transient

- Automatic pipe sectioning based on steady-state acoustic velocities

- Compound transient event logic to model complex control sequences

- Scenario Manager to track all design variants and operational possibilities in a single model file

- Integrated graphing and reporting

- Animation tools for visual interpretation of complex transient interactions

- Generates force imbalance files that can be automatically read into CAESAR II ®, ROHR2, AutoPIPE and TRIFLEX ® pipe stress dynamic models

- 2D flow diagram or isometric view interface

- Built-in libraries of fluids (including NIST REFPROP and ASME Steam Tables) and fittings which can be extended and customized

- Chempak™ add-on utility provides a thermophysical database of almost 600

- gases – allows you to define non-reacting

- pre-mixtures and simulate dynamic flow mixing

Primary Features of AFT

Reporting Features

Manage Design Variants

Refine and Report Raw Data

Visualize Your Results

Manage Design Variants

- Organize your design variants, operating conditions, existing infrastructure and expansions into a single file with Scenario Manager

- Batch run operating scenarios and export your results to Excel

- Easily compare design variant input to isolate changes between systems

- Quickly review model input from a schematic

- Compare transient response in different operating scenarios on a single graph

Refine and Report Raw Data

- Customize and organize parameters to isolate relevant information

- Report in multiple units, which can be updated without re-running your model

- Filter your results to identify areas of concern

- Export or copy results to Excel for further analysis

- Use design alerts to quickly identify parameters outside of allowable tolerances

- Report parameters section by section in your model

Visualize Your Results

- Save time with report-ready graphs

- Manage graph items and templates to re-use and compare different system set-ups

- Graph or animate parameters along a pipe length to see pressure and flow transmission

- Graph multiple parameters over time to understand system cause-and-effect

- Integrate flowrates to measure total flow over time

- Visually associate parameter results with locations in the system

- Color code your system to reflect parameter result range

- Color animate pipes in your system to see transient behavior in context

Modeling Features

Usability and Convenience

Pipes and Components

Fluid Properties

System Interaction

Transient Specific

Usability and Convenience

- Select pipe materials, sizes, type and schedule from built-in or custom databases

- Use built-in handbook data and heuristics for common component losses, embedded into pipes for visual simplicity

- Collect and catalogue common component and pipes into custom libraries

- Reduce redundant specification by importing your model file

- Draw your model as an isometric or on top of an aerial photography background

- Quickly make changes to common pipes and components with Global Edit

Pipes and Components

- Model component losses with Cv, K, Kv, or resistance curves

- Take control over your flow and pressure with control valves, determining valve position, capacity, and failure response

- Utilize reactionary components like check valves, relief valves, and vacuum breaker valves to confirm your system response

- Model relief valve protection, both internal or venting to atmosphere

- Display effective Cv and K factor values for all valves in the system

Fluid Properties

- Use built-in fluid databases or create your own to calculate properties

- Mix it up with fluid mixures in NIST REFPROP or the add-on Chempak database

- Refine your real gas modeling with equations of state (Redlich-Kwong, Three Parameter, Ideal Gas, Interpolation)

- Account for changes in composition, density, and viscosity with pipe specific fluid properties

System Interaction

- Utilize reactionary components like check valves, relief valves, and vacuum breaker valves to confirm your system response

- Model where your system sonically chokes and determine the resulting losses

Transient Specific

- Induce a transient response through a valve change, pressure change, pump changes and more!

- Use event logic to model interacting components in control systems

- Calculate and export forces for pipe stress analysis

- Size, locate, and test surge supression equipment like accumulators, relief valves, and vacuum breaker valves

- Consider variable friction modeling with large flow rate changes

- Use valve characteristic curves to capture specific valve response

- Use pulsation analysis to determine and analyze excitable frequencies (with add-on module)

AFT xStream Add-On Module

With this software extension tools, you can quickly and efficiently complete projects. Modules work within your existing AFT xStream models.